Bituminous Membrane Production Line Machinery

Production Process of Bituminous Membrane

Depending on the type of product (single-layer or double-layer), fiberglass and polyester enter the bitumen tank. Then, they are impregnated with primer or blown bitumen. Also, the layer thickness is adjusted by a channel installed at the top of the bitumen tank. Subsequently, the aluminum sheet adheres to the impregnated layer and enters the water trough. The layer cools down after passing through the water trough and between the rollers. In the next stage, the plastic backing layer is added, and the bituminous membrane layer enters the storage elevator. The elevator temporarily stores the bituminous membrane layer in the device, preventing production stoppage. Moreover, drying fans perform the drying operation of the bituminous membrane. Finally, the bituminous membrane enters the rolling machine and is rolled around a conical-shaped spindle, forming a roll (commonly known as a ball) with a length of 10 meters. After rolling, the layer is cut and ejected outside by the cutter.Continues Production Line Machinery

Continuous Glass Fiber Mat Autoclave

Bituminous Polymer or APP (Atactic Polypropylene) Coating

Insulation Cooling Unit

Insulation Tensioning Machine

Ongoing Insulation Reserve Machine

Moisture Barrier Packaging

Other Production Line Machinery

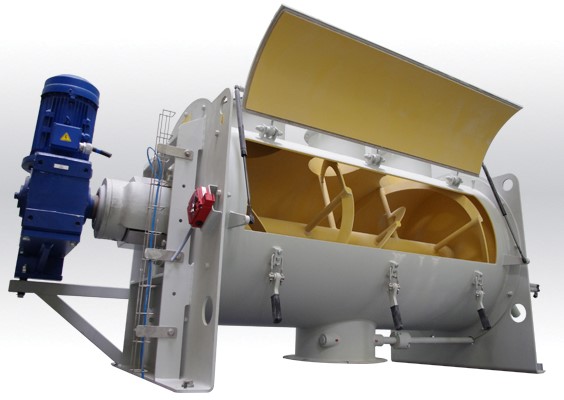

Mixer

Benzene Furnace