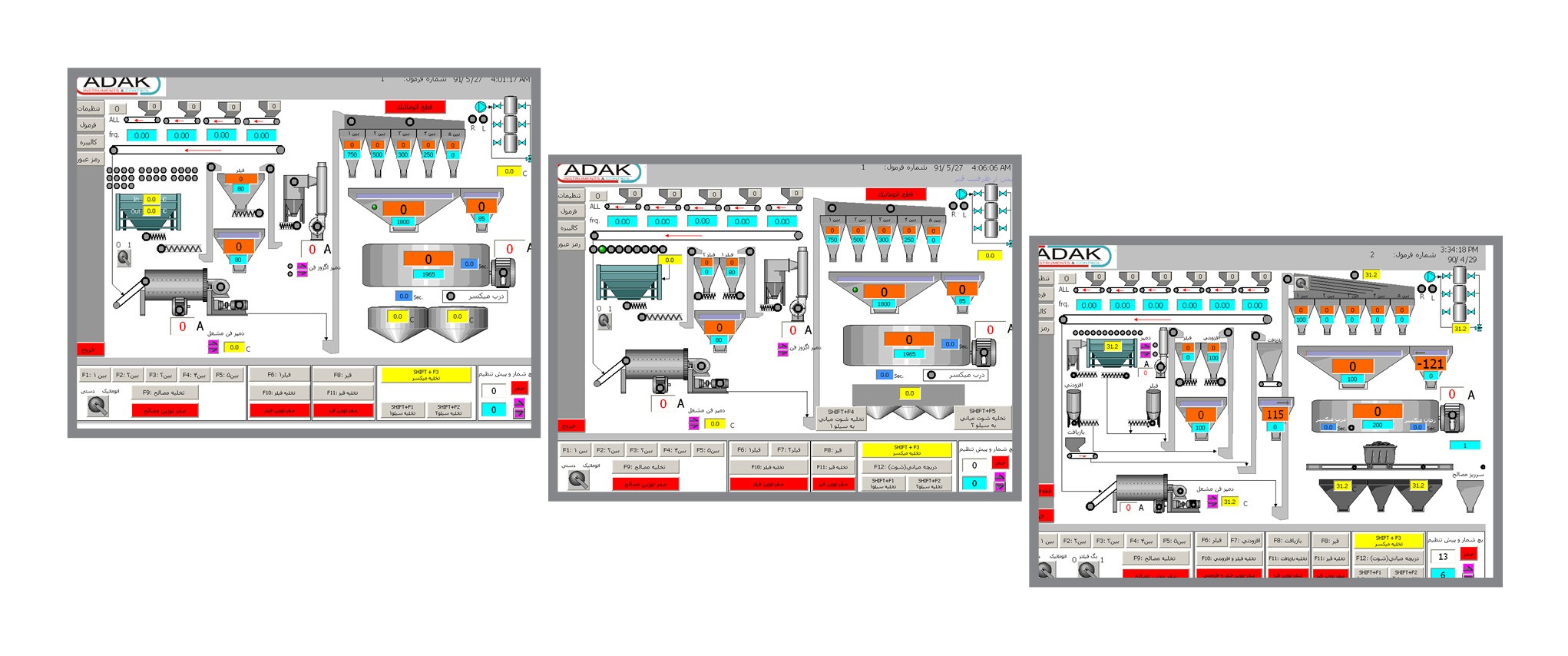

Control, Automation, and Monitoring Systems

The automation system for asphalt and bitumen processing plants is designed for customers seeking a system with no compromise on quality. This system is fully automated and controlled via PLC, providing statistical data that can help uncover trends, identify strengths and areas needing improvement, and anything in between. Internal statistical reports are stored, and data can be accessed via the internet. The process is automated, but manual control is also available if needed in any section.

Briefly, here are the control capabilities of the asphalt factory automation system, which are available for order:

Automatic or manual control of line inverters and speed adjustment of bitumen movement along the line

Precise control of bitumen weight and meterage according to defined values

Monitoring of level, temperature, and bitumen tanks

Temperature control of bitumen using formulas for fan inverters and burner control

Recording and displaying all events on a monitor in real-time

Statistics on the total consumption of materials, bitumen, fillers and additives, polymers, and total asphalt produced

Ability to define access levels and passwords for operators

Wireless parameter display and data gathering from mobile or PC.

Briefly, here are the control capabilities of the asphalt factory automation system, which are available for order:

Automatic or manual control of line inverters and speed adjustment of bitumen movement along the line

Precise control of bitumen weight and meterage according to defined values

Monitoring of level, temperature, and bitumen tanks

Temperature control of bitumen using formulas for fan inverters and burner control

Recording and displaying all events on a monitor in real-time

Statistics on the total consumption of materials, bitumen, fillers and additives, polymers, and total asphalt produced

Ability to define access levels and passwords for operators

Wireless parameter display and data gathering from mobile or PC.